What is Water Softener Regeneration?

Water softener regeneration is the process that clears out the minerals it has trapped from hard water. When hard water flows through the softener, the calcium and magnesium are swapped with sodium. This happens in a part called the resin bed. Over time, this bed fills up with minerals and can’t work properly. That’s when regeneration steps in. The purpose of regeneration is to wash away those trapped minerals so the softener can keep doing its job.

How the Regeneration Cycle Works

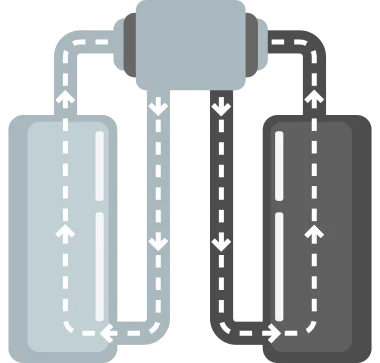

The water softener regeneration cycle starts when the resin beads can’t hold onto any more minerals. At that point, a salty water mix—brine—gets pulled in through a tiny injector that works by suction. The brine goes through the resin bed and knocks out the calcium and magnesium.

It doesn’t do everything at once. Each cylinder gets cleaned one by one, which means you still get soft water during the process. After the brine runs through, clean water comes in to rinse off whatever’s left. The full water softener regeneration steps include pulling in the brine, cleaning the resin, and then rinsing. How much water it uses and how long it takes mostly depend on the softener’s design and size. In short, to regenerate a water softener means flushing out the junk with salt and water so the resin bids can work like new again.

Why Regular Regeneration is Important

Soft water makes daily life easier—from bathing to cleaning. But for it to stay soft, the softener has to keep working as it should. That’s why regular water softener regeneration matters.

How Often Should Water Softeners Regenerate?

Typically, every couple of days to every couple of weeks, however, the timing of water softener regeneration depends on a few things.

First, how much water your household uses. If you have a big family or use lots of water at the same time each day, your softener will need to clean itself more often. Another thing to consider is how hard the water is in your area. Water with higher mineral content fills up the resin bed faster.

Then there’s the system itself. Some water softeners are built to regenerate on a fixed schedule, while others only do it when needed. Automatic water softener regeneration systems are easier to manage—they measure water usage and start the process at the right time. Manual systems need you to set a timer or do it yourself. If your softener stops regenerating or doesn’t finish properly, you might see signs like hard water coming through, soap not lathering, or the machine making strange noises. In those cases, check the salt level, inspect the system, and call for Harvey support – call us.

Request your free personalised quote today!

Do you need a water softener?

If it’s 100ppm or above, you have hard water. A water softener can help you avoid limescale buildup, saving time and money.

* PPM stands for parts per million and indicates the concentration of dissolved limescale minerals like calcium and magnesium in water.

How Harvey Water Softeners Supports Effective Regeneration

Harvey Water Softeners are made to make the whole water softener regeneration process easy and smooth. They use block salt to create a clean brine mix that does the heavy lifting. Each system is designed to keep running while one part regenerates, so you’re never without soft water. Benefits of water softener regeneration with us:

- Reliable Systems and Services – Harvey softeners are made in Britain, built for real homes, and tested for long-lasting use.

- Expert Maintenance and Support – You can always get help if something goes wrong. Water softener maintenance is quick and simple.

- Fewer products – Softer water means more bubbles and less soap. You save money on cleaning and bathing supplies.

- Soft on skin – The water feels smoother, which is great for washing, bathing, and even laundry.

- Less time cleaning – No more hard water stains or chalky spots. That means less time spent scrubbing.

Want to see the difference for yourself? Request your free quote today and find the perfect water softener for your home.

Frequently Asked Questions

The UK’s #1 selling Water Softener

Once you submit your details, what happens next?

- We’ll call to understand your requirements

- We can provide a water softener demo, either in your home, or virtually online.

- Receive a personalised quote based on your household’s needs.

- Start enjoying the benefits of soft water.

90-Day Money Back Guarantee

Fill out this form and one of the team will be in touch or call our team to speak to one of our experts 01483 753404.